The first thing that had to be done

was to clear enough land in order to accomodate for the length of the

tower (106 feet tall) when it is laying down flat on the ground and

also the guy wires that are attached . I was fortunate enough to have a

father-in-law (

www.collinsmountaingrading.com)

who owns a small skidder and was able to clear all the trees out. I

ended up using alot of the trees to build what I call the power

station. I just used a framing hammer, nails, hatchet for debarking and

a chainsaw for cutting. With those tools I was able to frame the shack

up with no problem. As far as the roof of the shack, I used some tin

from Lowes and sheeter screws. The intersting thing about the tin is

that I got about a 60% discount on it. The reason was that the tin

looked like it had been left on the flatbed truck and in the rain for a

few days after delivery. It developed some sort of white scale all over

it making its appearace look bad and unsaleable. Turns out that Lowes

and other home improvement stores usually have a good bit of materials

that are damaged or can't be sold at full price. Ie scaly , rusty tin,

busted concrete bags, bent boards, cracked plywood, pressure

treatedwood, chiped concrete blocks etc. What I do now is whenever I am

Lowes, homedepot, etc, I ask them if they have any damaged building

materials they are trying to get rid of. Alot of times they are. If

this is the case I usually get anywhere from a 50 to 75 % discount on

these. You can ususally negotiate more when you tell them you want

it "all". Thats less work for them to have to move it, throuw it

away, load it back into the truck, etc... The twelve sheets of roofing

tin for the power station were bought for 7 bucks a sheet. Normally

they are $17 a sheet. I saved a bunch Of money that day. Also regarding

electrical wire at Lowes and others, if someone gets wire cut there and

then they just decide not to buy it, then this wire is usually sold at

1/2 price. Pretty sweet deal if they have what you happen to need at

the time. I always look around to see precut / taped up wire laying

around. If I need it I grab a lowes person and have them mark it down

50%. Thats their policy and my savings.

Once the land was cleared I had to lay out the

footers for the tower. There are 6 footers all together. One in the

middle to support the tower itself and 4 that surround the middle

footer for the 4 sets of turnbuckle assembly's that attach to each

section of pipe going up the tower. The tricky part was calculating how

much concrete to order. According to the A.R.E tower manual

the footers

needed to be 3 feet by 3 feet by 4 feet. To calculate the amount of

concrete to order I used a concrete calculator found at

http://www.concrete.com/calculatorsmaterials.htm#volume

You need to know how many yards to order so that you have

enough but you also want to be careful not to order too much because it

can be a waste of money (I ordered too much - oops) I ordered my

concrete from Pugh Concrete out of Silk Hope/Pittsboro North Carolina

(919) 542-0321. I ended up

ordering 12 yards of 4000 psi concrete at $108 dollars a yard plus

$5.50 a yard for fiber so really $113 a yard. Fiber is fiberglass

and they mix it in with the concrete and it makes it very strong. I

guestimated 12 yards because some of my footers were 4x4x5 and 3x4x4

and so forth which are larger than the recomended 3x3x4 in the A.R.E

manual. The concrete guy said said that there was about 3/4 of a yard

left in

the truck after we poured the six footers and was wondering what I

wanted to do with it. He offered to take it back to the office but said

I would not get any money back of course.

I had an idea. What if I just got some of those logs left over from

clearing out the land and build a square on a flat part of the ground

somewhere and have him pour the extra concrete right into the makeshift

form. Thats what we did and I took another board and pushed it right

down the middle to make 2 sections within the log square on the ground.

Now I have 2 squares of concrete about 6 feet by 3 feet by 8 inches. I

now

plan to use these two footers in the future to mount more solar panel

frames to. I guess it wasn't a waste of money after all. I'll need to

borrow a tractor or skidder to move them around of course.

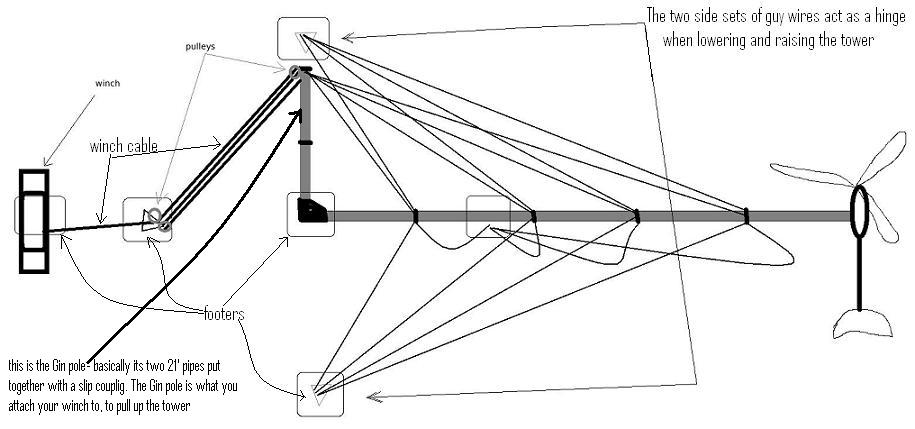

The sixth footer

is

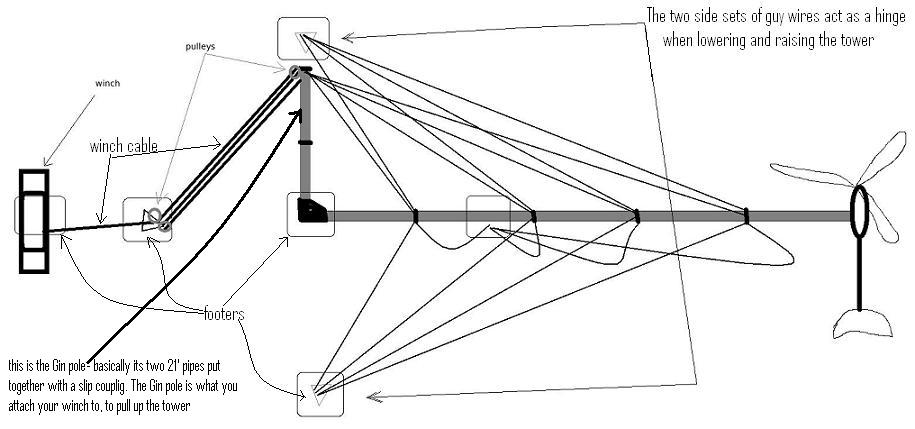

for mounting the winch which is used to pull the

tower up via the gin pole (the shorter part of the L ) -- see drawing

below.

If you follow the manuals for the tower assembly and footer layout, it

is pretty self explanatory.

Here is a link to the Turbine Tower mechanical manual.

ARE110-48V_Owners_Manual_Mechanical_Ver5.0.pdf

For the footer layout, it was crucial that

we had a "transit level" so that we could make sure to build any

concrete forms

to the same height so that when we poured the concrete, the tops of the

footers would all be at the same elevation in relation to each other.

If the footers are not at the same height then lowering and raising the

tower would be harder to do since you could have one set of guy wires

on one side be shorter or longer than the other. These guy wires act as

the hinge for raising and lowering the tower.

Rockriver.us

Rockriver.us Rockriver.us

Rockriver.us